The temperature of hot mixed asphalt is a critical component to the compaction and longevity of poured concrete. The ideal temperature for hot mix asphalt pavement when it arrives at a project is between 275°F and 300°F. In many states, asphalt temperature is regulated and is required to be maintained and delivered to the project sites within the ideal temperature range or else the load is considered void.

To help monitor asphalt temperatures and ensure that no load leaves the site without being at the appropriate temperature, one hot mix plant created an IIoT-based application to measure and record the temperature of the asphalt at the time it was loaded onto the truck.

Products Used

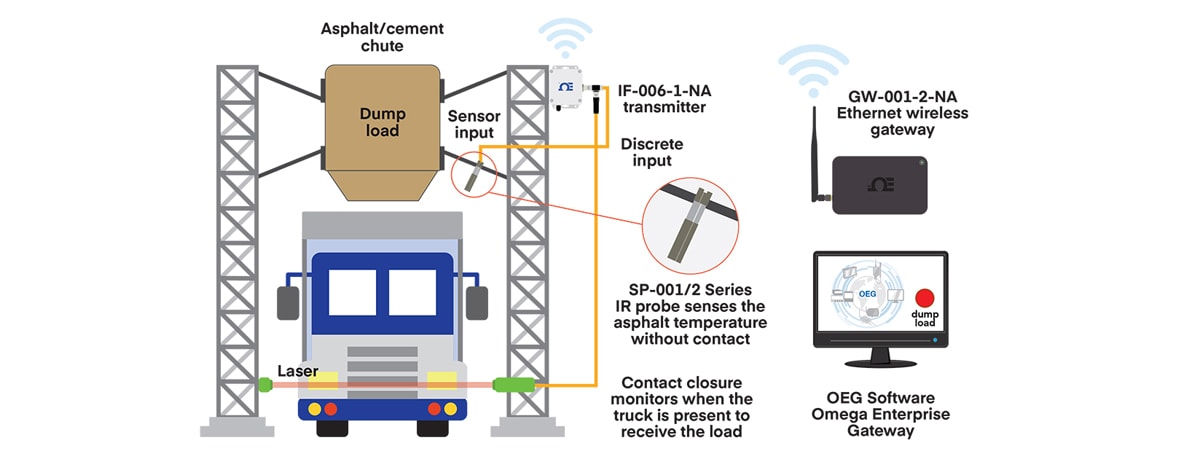

The diagram illustrates the IIoT-temperature monitoring system used in this application. The system includes three products:

SP-001-0 Smart IR Temperature probe This infrared non-contact temperature smart probe includes a modular design for wired and wireless connectivity. The probe provides high accuracy measurement of temperatures between -20° C and 600° C and features modular plug and play functionality.

XW-ED-PRO Smart Wireless Transmitter This rugged high-performance and low power consumption wireless sensor/transmitter system transmits data from any Layer N Smart Probe, such as the SP-001-Series. The radio is an IEEE 802.15.4 compliant transmitter operating at 2.4 GHz designed to transmit up to 1000m* (3280') outdoor and around 100m* (328') indoor.

ZW-REC Wireless Receiver This receivers provides robust wireless connectivity to a XW Series transmitter, and connects via Ethernet to either a PC or Server where OEG 2.0 software can reside for local and cloud data storage, alarming, and analytics.

M12-8 Extension Cables This application also requires a M12 extension cable to connect the SP-001 to the XW-ED-Pro. Choose from the options below based on the distance between XW and SP-001.

M12-8 Extension Cables for Probes

DM12CAB-8-1-RA

1m (3.3') cable dual M12-8 connector, right angle terminator

DM12CAB-8-3-RA

3m (9.8') cable dual M12-8 connector, right angle terminator

DM12CAB-8-5-RA

5m (16.4') cable dual M12-8 connector, right angle terminator

M12-4 Accessories-PRO Model This application also requires a cable to connect the XW-ED-Pro to the proximity sensor. Choose from the options below based on the distance between XW and Prox sensor.

M12-4 Accessories-PRO Model

M12C-P24STPC-SFSR-FL-3

iPROX Series Proximity Sensor The iProx represents the highest performance, most versatile tubular inductive sensor offered by OMEGA. By utilizing an embedded microprocessor and exclusive SmartSense™ technology, iProx can sense up to three times farther than typical sensors of its class. With extended sensing range, quality construction, and the ability to automatically configure its output for sinking or sourcing connection, iProx is the ideal choice for even the most demanding inductive sensing applications.

A hot mix manufacturer can maintain compliance with state regulations by having an accurate record of the temperature of each load when it leaves the plant. Additionally, because the manufacturer receives real-time notifications when a load’s temperature doesn’t meet requirements, the temperature monitoring system provides an additional level of quality control and ensures that no load leaves the plant that doesn’t meet temperature requirements.

Using a wireless version of the Smart Probe can save hours of installation time. Additionally, quick connect modular M12 connectors and cables ensure connections are robust and watertight.

M12, 4-pin straight socket to stripped leads cable - 3m

M12C-P24STPC-SFSR-FL-5

M12, 4-pin straight socket to stripped leads cable - 5m

M12C-P24STPC-SFSR-FL-10

OEG Software Easily connect your OMEGA devices into your infrastructure. The OMEGA Enterprise Gateway software (OEG) uses an intuitive web-based interface to make monitoring and control simpler and more intelligent. The software provides 24/7 real-time monitoring and historical data analysis, alarm and event notifications, and encrypted ethernet connectivity. It supports to support the needs of enterprise customers looking for on-premise solutions while offering Layer N Cloud integration out of the box for mobile data access and notifications.

How it Works

Result

Pro Tip

CLOSE

CLOSE

Industrial setups look to reap the benefits of the Industrial Internet of Things by establishing a connected environment.

Industrial setups look to reap the benefits of the Industrial Internet of Things by establishing a connected environment.